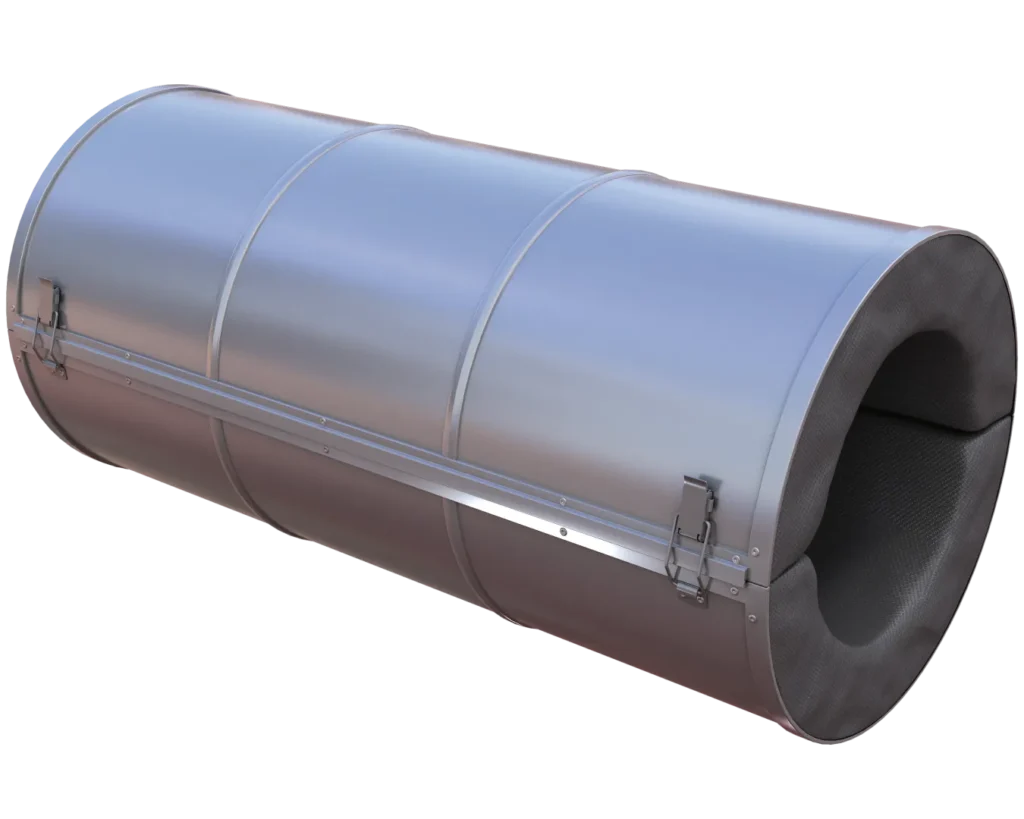

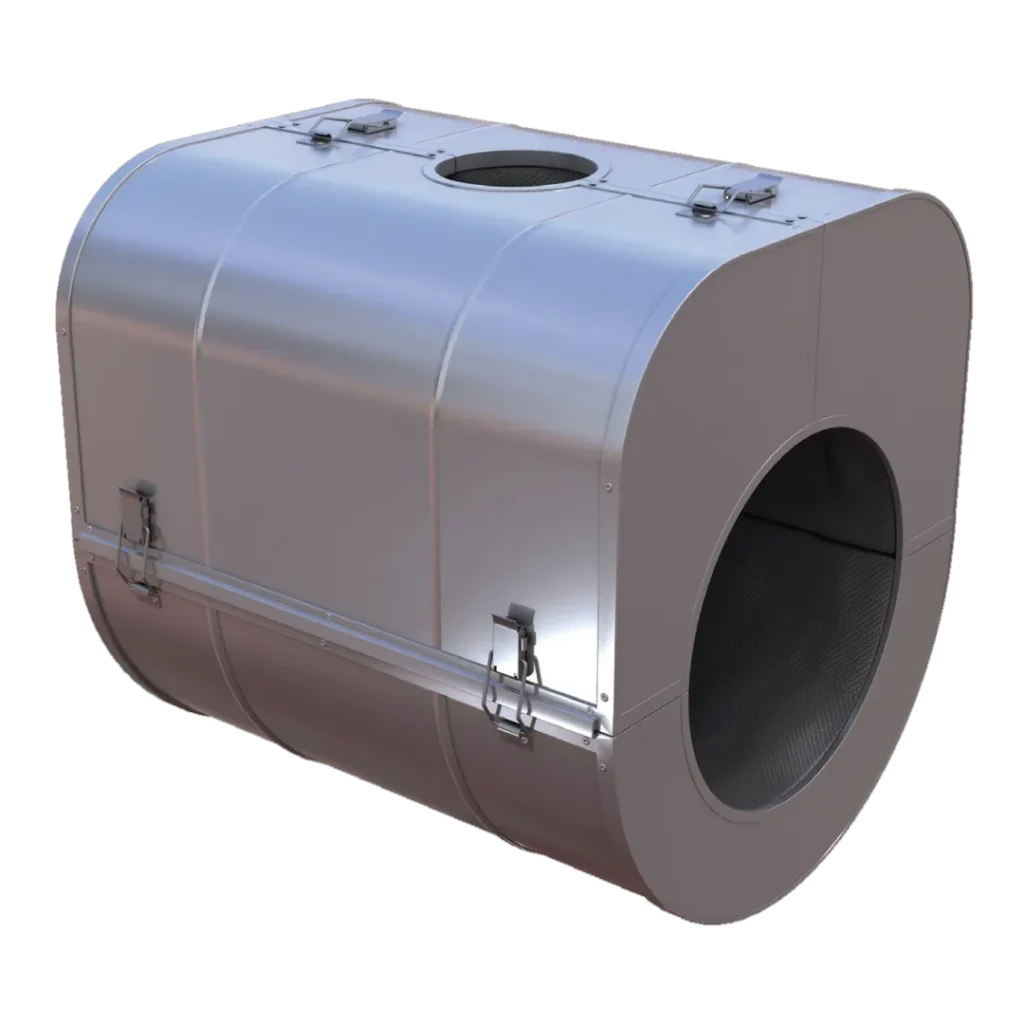

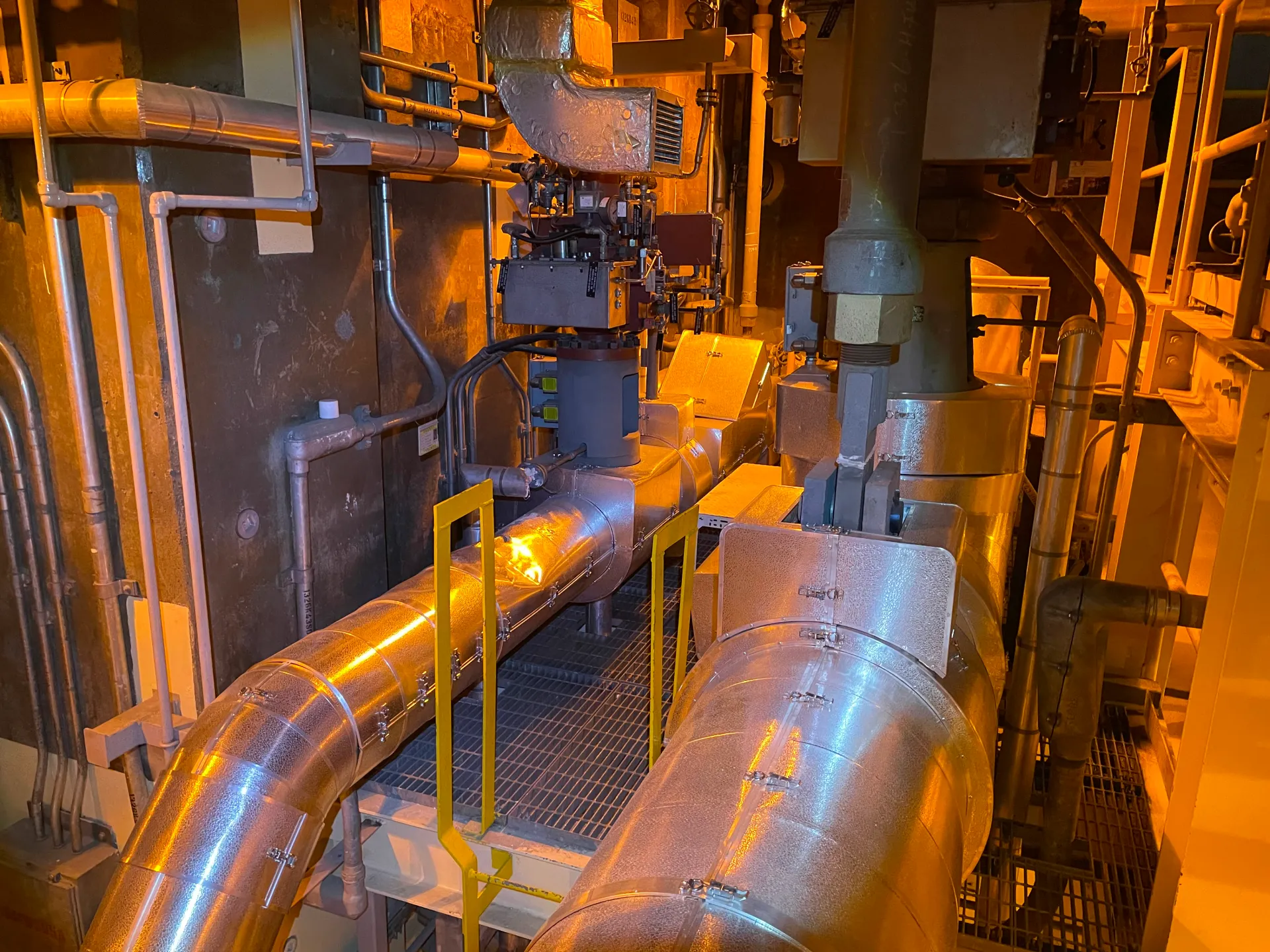

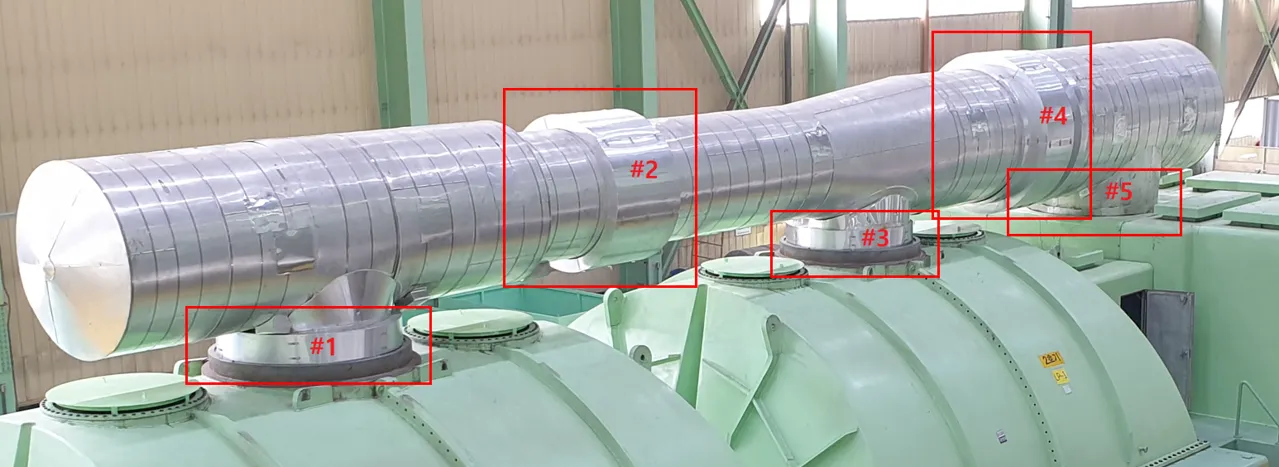

Annual inspections and frequent weld repairs on a P91-to-A106B transition spool of the HP bypass piping required full insulation and jacketing removal and replacement, adding material costs and at least two days of downtime per event. To eliminate this recurring burden, RAPID was designed for approximately 33 feet of 18-inch, 1000°F piping to enable fast removal and reinstallation during future inspections and weld repair work. After RAPID implementation, insulation installation time dropped by 94% and annual insulation replacement costs were reduced by nearly 100% due to reusability.